Biomass availability and logistics

For the realisation of the green natural gas ambition in the Netherlands, annually 240 PJ of SNG has to be produced. In addition to this ambition, there are also additional targets for implementation of biomass for the production of power, fuels, and chemicals. In the Netherlands there is insufficient biomass available to meet all the targets. Therefore, large-scale import of biomass is required.

Globally, sufficient biomass is available for energy applications to substitute up to 60% of the global energy consumption on the long term, without competition with biomass applications for food and materials [1]. Therefore, it is realistic to assume that biomass can play the projected role in the Dutch energy infrastructure for the production of SNG. However, the condition to actually realise the biomass large-scale implementation is the construction of a global biomass trade and logistics system. Even more important is incorporation of guarantees (e.g. certificates, controls) to ensure sustainable production of the biomass.

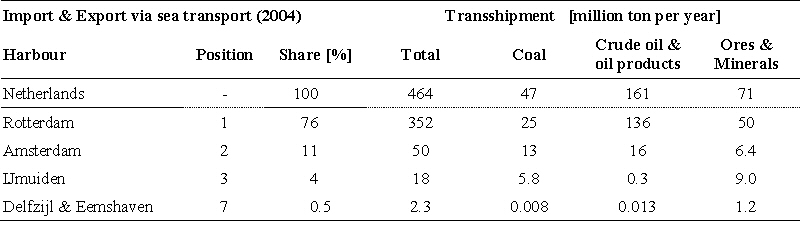

To produce annually 240 PJ of SNG in the Netherlands approximately 20 million tonnes of imported biomass is required. For certain, this is a large amount. Today, the necessary biomass logistics infrastructure is not available, although in the Netherlands there is much experience in transshipment of e.g. coal and cattle feed. To assess the feasibility of the projected logistic schemes, a comparison is made with the existing practice of import and transshipment in the Netherlands. In the table below the transshipment of selected materials in the top 3 harbours of the Netherlands and in the harbour of Delfzijl is shown [2].

The required amount of 20 million tonnes of biomass corresponds to ± 4% of the total current annual transshipment in the Netherlands and is less than the current annual transshipment of coal in the Rotterdam harbour. Furthermore, the current transshipment of wood and pulp is already half the amount of biomass that is required for bio-SNG production and the grain transshipment is already one third of that amount. Considering the existing practice and experience in the Netherlands, the targeted biomass import for SNG-production is feasible.

SNG will be produced from imported biomass, which will initially be primarily clean woody biomass form production forests. In several studies optimum biomass import schemes have been assessed for large-scale synthetic transportation fuels from biomass [3-7]. Most important conclusions of those studies, which generally apply, are:

- Transport costs can be significantly reduced when densification is performed, e.g. by producing wood pellets, pyrolysis-slurry, or pellets of torrefied wood.

- Investment costs for biomass pre-treatment and densification are compensated by the lower transport costs.

- Biomass pre-treatment by torrefaction has advantages with respect to allowing higher gasification efficiencies and cost reduction in intermediate storage, in addition to the transport advantages.

In the case of SNG being the desired product, other transport options are possible. In addition to biomass import and SNG production in the Netherlands, also the option can be selected of SNG production in the country of the biomass origin and subsequently transport the SNG to the Netherlands in the form of CNG (compressed natural gas), LNG (liquefied natural gas), or by pipeline. ECN is currently (mid 2006) performing an assessment of the various biomass import and SNG production routes.

References:

J. Gigler, H. Boerrigter, M. van Burgel, P. Cnubben, R. Hoogma and J. Wempe: Vol gas vooruit; De rol van groen gas in de Nederlandse energiehuishouding, startnotitie voor de werkgroep Groen Gas. On behalf of “Platform Nieuw Gas”, 20 June 2006, The Netherlands.

Statistics Netherlands (CBS), 2006 (www.cbs.nl)

H. P. Calis, J. P. Haan, H. Boerrigter, A. van der Drift, G. Peppink, R. van den Broek, A. Faaij and R. H. Venderbosch: Technical and economic feasibility of large scale synthesis gas production in the Netherlands from imported biomass feedstock – a Strategic Decision Analysis study. Pyrolysis and gasification of biomass and waste, 30 September - 1 October 2002, Strasbourg, France

A. Faaij, R. van den Broek, B. C. W. van Engelenburg and E. Lysen: Worldwide potential of bio-energy and possibilities for large scale international trade; - technical analysis and policy aspects. In the proceedings of the 5th international conference on greenhouse gas control technologies, 2000.

A. van der Drift, R. van Ree, H. Boerrigter and K. Hemmes: Bio-syngas: key intermediate for large scale production of green fuels and chemicals. In the proceedings of the 2nd World Conference on Biomass for Energy, Industry, and Climate Protection, 10-14 May 2004, Rome, Italy.

H. Boerrigter and A. van der Drift: Biomass pre-treatment for biomass-to-liquids (BTL) plants. ECN, ECN-CX--05-087, 2005, The Netherlands (confidential).

R.W.R. Zwart, H. Boerrigter and A. van der Drift: Integrated Fischer-Tropsch diesel production systems. ECN, ECN-CX—06-033, 2006, The Netherlands (confidential).