Experimental line-up

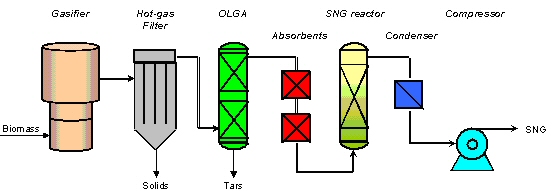

Starting point in the development of the technology line-up for an integrated bio SNG system was the lab-scale system developed and demonstrated for Fischer-Tropsch synthesis from biomass gasification gas. This system is shown in the figure below and discussed in reference [1]. Biomass is gasified and the raw product gas passes a high-temperature gas filter operated at 400°C to remove essentially all the solids. All the tars and a maximum amount of the BTX are removed in the OLGA unit. The gas leaving OLGA at a temperature of 60-100°C is further cooled and cleaned from NH3, HCl, and other inorganic impurities in a water scrubber at room temperature. Water is condensed from the clean gas and subsequently the gas is compressed to the desired pressure (30 to 60 bar). The compressed gases are passed through a ZnO filter to remove the H2S and an active-carbon guard bed to remove all remaining trace impurities.

Characteristic of this line-up is the atmospheric gasification in combination with the pressurised (30 to 60 bar) methanation. To allow intermediate compression, the product gas needs to be free of condensable compounds like residual tars and especially water. After compression the gas is almost completely dry, whereas in the methanation steam needs to be added to prevent coking and soot formation (see below).

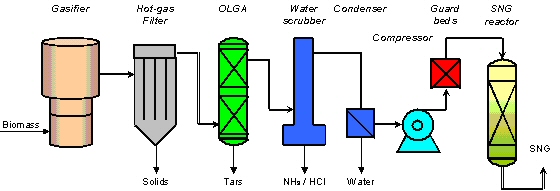

The requirement for the addition of significant amounts of steam might be a serious efficiency loss, especially when low-value residual heat (~200C) is missing. The overall system efficiency could be increased when water condensation (both in the water scrubber as well as in the condenser) could be avoided therewith decreasing the steam demand for the methanation. Therefore, an alternative plant line-up was developed within the project as shown in the figure below.

Characteristic of this line-up is the performance of the gasification and methanation at the same pressure level (atmospheric in the lab-scale line-up). Water is condensed after the methanation and the product SNG is compressed to the desired pressure. Furthermore, gas cleaning is performed with adsorbent materials and not with a water-based wash process (i.e. a scrubber). Consequently, a new gas cleaning had to be designed and the methanation reactor had to be designed for atmospheric instead of pressurised operation.

Both line-ups were built and demonstrated, however, the technology development was focussed on the line-up without intermediate water condensation and pressurisation.

References:

H. Boerrigter, H.P. Calis, D.J. Slort, H. Bodenstaff, A.J. Kaandorp, H. den Uil and L.P.L.M. Rabou: Gas cleaning for integrated biomass gasification (BG) and Fischer-Tropsch (FT) systems. ECN, ECN-CX--04-004, 2004, The Netherlands (confidential).